Learn how products are made in the fashion industry with a product development and production with Shallow Fashion.

This part-time position has a focus on small business and domestic production, but some Shallow Fashion clients do high volume, overseas manufacturing as well.

Requirements

• Must have studied, or be passionate for product development and design

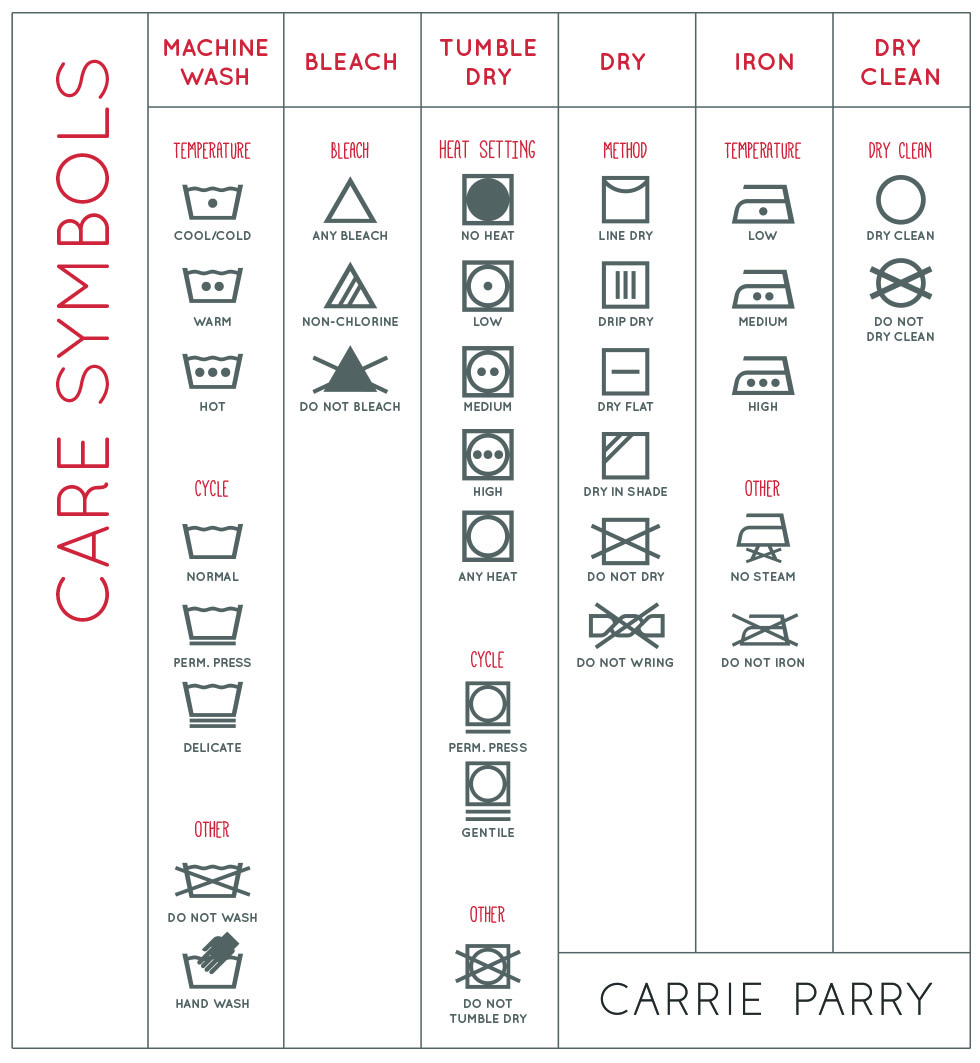

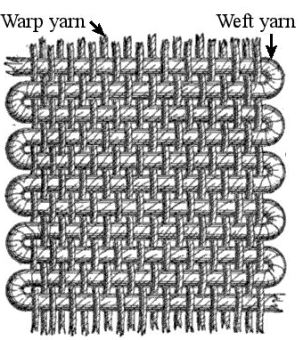

• Basic knowledge of fiber, fabrics and trim a plus

• Must have inherent understanding for how to make things

• Must be available at least two full 8 hour days a week

Responsibilities

Shallow Fashion's product development intern will work directly with designers and the production director during the sampling and development process. This will be an in-depth exercise to ensure all products are ready for bulk production.

This process will teach the intern construction and how things are made, as well as learn how to communicate ideas to factory partners.

The intern will assist in cataloguing all raw materials & costs for each product, which will teach the intern how to build BOMs (bills of materials), which is an invaluable element of making products.

Intern will participate in linesheet & lookbook photoshoots, as well as all pre-production tasks as they pertain to market.

Intern will learn cross-functional skills, working closely with sales and marketing.

Compensation

Day rate - $150.00 (8 hours/day, at least two days a week)

+Hourly - $15.00/hour as-need, on call (can be done from home or in office)

To Apply

Email: courtney@shallowfashion.com